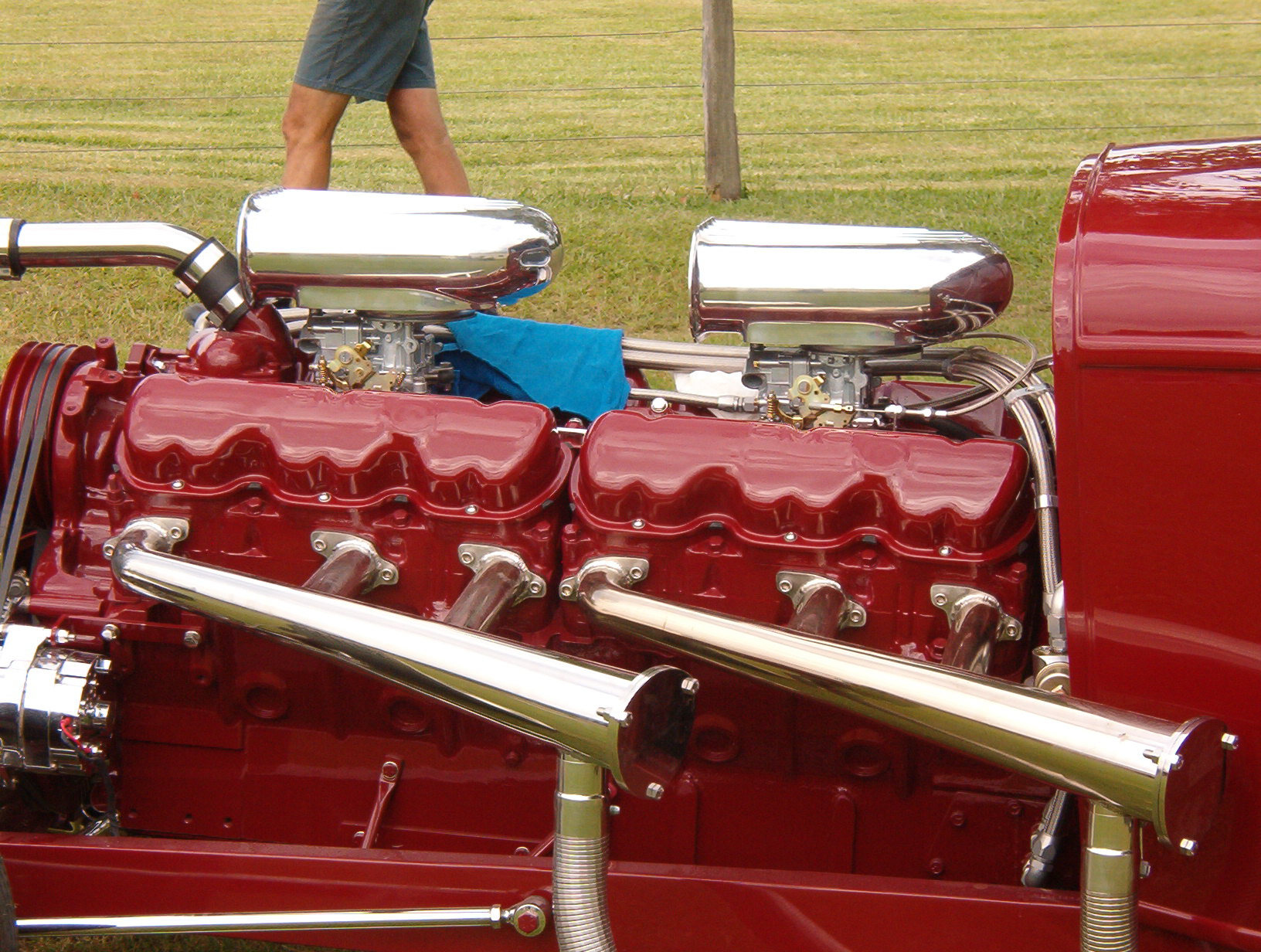

V 12

![]()

THE LATEST ROD BODS DOWNUNDER

PROJECT

THIS IS A

ONE OFF - UNIQUE

The Only 32 Three Window Coupe

powered by this extremely rare motor

The Rod Bods Downunder

Fibreglass 1932 Three Window Coupe Body is powered by

a GMC V12 Twin Six Motor (702 Cubic Inch) with a Turbo 400 Gearbox.

The body

has been mounted on a 32 Chassis

The interior has been fitted with black leather

bucket seats and has been fully trimmed with black leather and carpet.

A set of six Dolphin Gauges have been mounted

into the 32 Dash Panel, a 21 circuit wiring harness and pulse generator have

been installed.

All external hinges and dress-up chromed

This vehicle has been sold

The king of GMC's

gasoline engine family, the power-laden 702 Twin-Six. It makes

words like durability, performance and operating

economy take on a whole new meaning. It's

true truck horsepower and tremendous torque at low r.p.m.

take on the biggest jobs with an

easy-stroking effort. It digs into grades and requires far less gear shifting

to keep in step.

With relatively slow operating speed, of

only 2400 maximum r.p.m., the Twin-Six combines

ideal fuel / air mixture, economical 2-barrel carburetion, low internal

friction, short

stroke, and good exhaust scavenging to add years to engine life and squeeze

every Mile

from every gallon of gasoline.

The Twin-Six's 60

degree "V" type design compacts it's massive

strength. But ruggedness

does not stop there. For example, it's valve train is

the most outstanding of any production

vehicle. In trucks, engine life is largely determined by valve life. So in the

702, push rods,

lifters, rocker arms, shafts and the valves themselves are made from the best

quality,

commercially practical material available; larger, more

sturdy than valve trains in other

engine of comparable output. It's short stroke reduces

internal friction . . .

gives full power with less piston travel.

Result is less engine wear . . . longer engine life.

Peak torque is reached at low r.p.m. and maintained

over a wide range of engine

speed for longer sustained power. The toughest jobs are handled in stride.

Oil and fuel consumption is low . . . maintenance and service cost are low . .

.

save you money four ways.

It has the highest cooling and lubricating ability of any comparable size

engine.

This means greater engine efficiency . . . longer trouble-free service.

56 major parts are interchangeable between the Twin-Six and all other GMC V-6

engines to provide greater parts availability and standardization.

High mounted camshaft . . . short push rods . . . big, tough, long-lived valves

combine to make an exceptionally rigid, durable valve train. Again . . .

lower cast, longer life, more economy.

Strength where strength counts ! Exceptionally,

rigid crankshaft . . . massive connecting rods . . .

big, rugged, heavy-duty pistons. Many thousands of

miles of dependable service.

THE HIGH OUTPUT OIL PUMP

capable of pumping 17 gallons of oil per minute, provides extra circulation at

all

engine speeds . . . extra protection and well oiled

surfaces on all vital moving parts.

Engine is lubricated as soon as it's started. Cam lobes dip into a built-in

reservoir

of oil as the camshaft rotates, preventing cam and valve scuffing -

a major reason why this engine gives long, dependable service.

118 GALLONS OF WATER

(at 2400 r.p.m.) Are pumped through this engine every minute.

With thermostat open, only

half the water goes to the radiator, the other half returns to the pump through

a by-pass.

This results in excellent cooling ability. There is less than four degrees

variation in

water temperature throughout the engine. This checks the possibility of hot

spots. Here's

cooling efficiency that is not matched by any other comparable size engine.

Life of pistons,

valves, valve guides and spark plugs in much greater, and the possibility of

head-cracking

is held safely in check . . . further proof of the

durability and long

life that is built into this engine.

POSITIVE CRANKCASE VENTILATION

is provided by using manifold vacuum to draw fresh air through the engine. Air

enters through a

replaceable paper-element breather, travels up through the crankcase to the

cylinder head

covers, then through air flow regulating valves directly into an intake port of

each head,

carrying with it, into the combustion chamber, harmful sludge-forming fumes and

moisture laden

air. Bearings and other precision parts last longer . . .

maintenance is less . . . engine life is extended.

Here's The Inside Story GMC's Twin-Six Engine

EXCEPTIONALLY RIGID, FORGED CRANKSHAFT

has 7 extra large main bearing journals . . . 6 extra large crankpins - one for each pair of

connecting rods, and all "Tocco" hardened. It's heavy construction makes it exceptionally

rigid. M400 main and connecting rod bearings, the best available, provide up to

7 times the

life of commonly used bearings. Crankshaft and bearings are freed from

torsional impulses

by a rubber type damper in crankshaft pulley.

CAST ALUMINUM PISTONS

cam ground; and with cast-in steel expansion control

band, eliminate piston slap. Pistons are

balanced to within 1.8 grams to ensure vibration-free performance. Long skirts

are precision-

ground and tin-plated to prevent scuffing during initial run-in. 4 rings, 3 compression, 1 oil

control - provide positive compression sealing . . . improved oil economy. Top

compression ring

and oil control rings are has chrome plating for longest wear. Top ring rides

in a cast-in steel

groove for even more durability.

HIGH STRENGTH, ALLOY IRON CAMSHAFT

Cam lobes and bearing journals are induction-hardened for great wear

resistance. Short, stiff push

rods provide for a rigid valve train and positive valve action. 7 large,

closely spaced bearings

keep camshaft precision-straight. Valves last longer . . . fewer adjustments

are needed . . .

service expense is lower.

FULLY-MATCHED COMBUSTION CHAMBERS

Smooth, precision-machined combustion chamber - rarely found in other engines -

minimizes carbon deposits,

hot spots and pre-ignition. And there is uniform combustion in all cylinders

for smoothest engine

operation. 6 equally-spaced head bolts (not 4 as found in other engines)

surround each cylinder to

reduce bore distortion . . . guarantee gasket sealing for long engine service.

Spark plugs, located

inside the "V", away from hot exhaust manifolds, run cooler, have

much shorter wires,

and are easy to service.

EXTRA HEAVY BLOCK AND CRANKCASE

is solidly cast of high strength, long-wearing iron alloy. A deep, 3-inch

ribbed skirt below the

centerline of the crankshaft provides rigid reinforcement to the crankcase.

Cylinders are widely

spaced and staggered, providing even greater block rigidity and much greater

cooling area around

the cylinder walls for long engine life. Heavy bearing caps and the use of 4

large cap screws on

the rear main bearing assure perfect crankshaft alinement,

minimize crankshaft deflection

and assure maximum bearing life.

ALUMINUM ROCKER ARM BRACKETS

Each of the 4 hardened steel rocker arm shafts is held

firmly in place by 5 aluminum brackets.

As valves warm up and expand, brackets expand too, assuring proper valve

clearance under all

operating temperatures. The engine runs quieter . . . fewer valve adjustments

are needed . . .

valve life is extended. Brackets at both ends of the shaft,

and one bracket between each set

of rockers arms holds shaft deflection in check. This plus the high-up

camshaft mounting and

use of short, stiff push rods provides an exceptionally rigid valve train. Just another way

you save on maintenance and get longer engine life.

TWIN INTAKE MANIFOLDS

with individual ports for each cylinder are a special feature of this engine.

Individual ports

permit faster intake and more uniform distribution of fuel-air mixture to each

cylinder.

Because manifolds are short and have a minimum of bends and curves, too rich or

too lean fuel

mixtures, usually found in longer in-line or V-8 engines are completely

eliminated. This results

in much better fuel economy, cleaner, more complete combustion and greater

engine efficiency.

TOP QUALITY HEAVY RIBBED EXHAUST MANIFOLDS

Interchangeable exhaust manifolds of special alloy iron and highly resistant to

cracking and

warping by extreme temperature changes. Large individual ports for each

cylinder and short,

large diameter passages permit more complete scavenging of exhaust gases.

Result is better

fuel economy . . . longer life . . . better performance.

FUEL FILTER,

is standard. It protects the carburetor from dirt and other foreign materials

that can cause

annoying engine failure and costly down time. The fuel filter is the

replaceable element type.

LARGEST VALVES

This engine has the largest diameter intake and exhaust valves of any

comparable size engine.

This means it is unsurpassed in volumetric, or breathing, efficiency.

Combustion is more complete,

scavenging of exhaust gases more thorough. The engine gets more work out of a

gallon of gasoline . . .

and stays cleaner longer, too. In addition, valves have short, large diameter

stems to reduce

possible distortion and dissipate heat quickly. Positive rotation of both

intake and exhaust

valves is an extra-quality feature. Short, rigid puck rods hold valve train

deflection to a minimum

and help keep engine in top running condition. Valve clearance is controlled by

self-locking adjusting

screws . . . tune-ups are easy . . . upkeep low.

HYDRAULIC GOVERNOR

Extra long life for heavy duty engines is assured by

the hydraulic governor. Operated by oil

pump pressure, this accurate, positive, and reliable governor keeps engine from

exceeding

it's proper operating

speeds.

The above Information came from GMC Truck

brochures put out in 1960. Further information can be located www.6066gmcguy.org

Engine Specifications

|

Engine Model |

Gross

Horsepower |

Net Horsepower |

Gross

Torque lbs. ft. |

Net

Torque lbs. ft. |

Bore -

Stroke |

Displacement |

Compression |

|

Twin-Six |

275 @ 2400

rpm |

250 @

2400 rpm |

630 @

1600-1900 |

585 @

1600-1900 |

4.56 -

3.58 |

702.4

cu. in. |

7.50 to

1 |

The 702 Twin-Six V12 was used in the B-, BW-,

L-, & LW-7000 series trucks.

Maximum Recommended Speeds in rpms:

702 V12 -- 2400

Valve Lash (Hot, Running)

V12 -- Zero

Cylinder Head Bolt Torque -- 65-72 ft-lbs

Idling Speed, Manual Trans, 400 - 450 rpm, Auto trans, 450 rpm

Oil Capacities

|

Engine Model |

Quarts |

w/ filter |

|

702 |

14 Qts |

16 Qts |

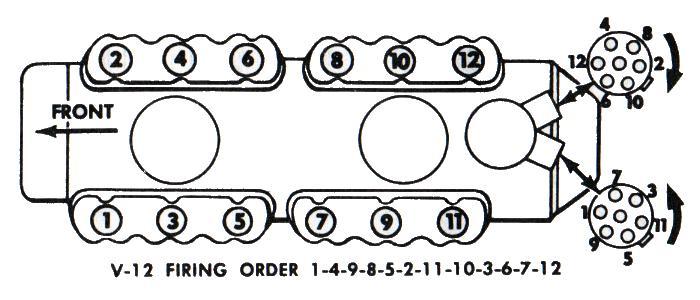

Firing Order

Twin-Six V12 Firing Order: 1-4-9-8-5-2-11-10-3-6-7-12

![]()

Copyright 2010